LOW-COST ELECTROCHROMIC GLASS MASS PRODUCTION TECHNOLOGY

Existing technologies are quite expensive

Restricted consumer attributes

Improved energy efficiency in buildings

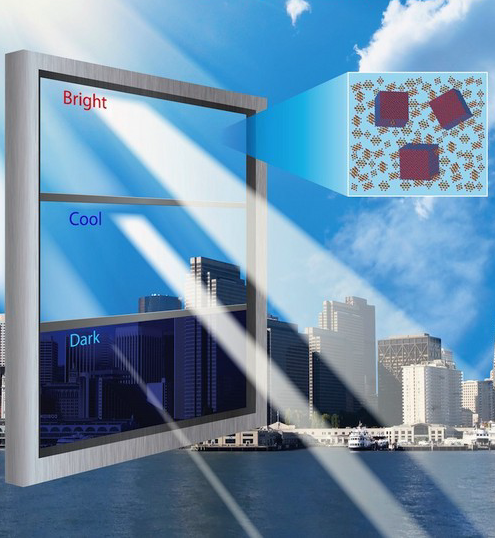

Electrochromic glass

An electrical potential once applied alters the transparency of the electrochromic glass in the visible optical range while also ensuring control of the amount of heat penetrating into a room. According to View Glass, this kind of glass reduces peak energy consumption for cooling and lighting by 20%.

Comberry has developed an electrochromic glass production technology based on durable materials for mass industrial application called TUNOX.

The TUNOX electrochromic materials offer an extended range of colors, including shades of blue, gray, black and more. The unique proprietary technologies used in the TUNOX material system addresses many of the challenges associated with production and operation of electrochromic glass substantially improving performance as well as the consumer appeal of darkened glass units and making production cheaper and «flexible».

The technology is ready to scale.

Architecture

Vehicles

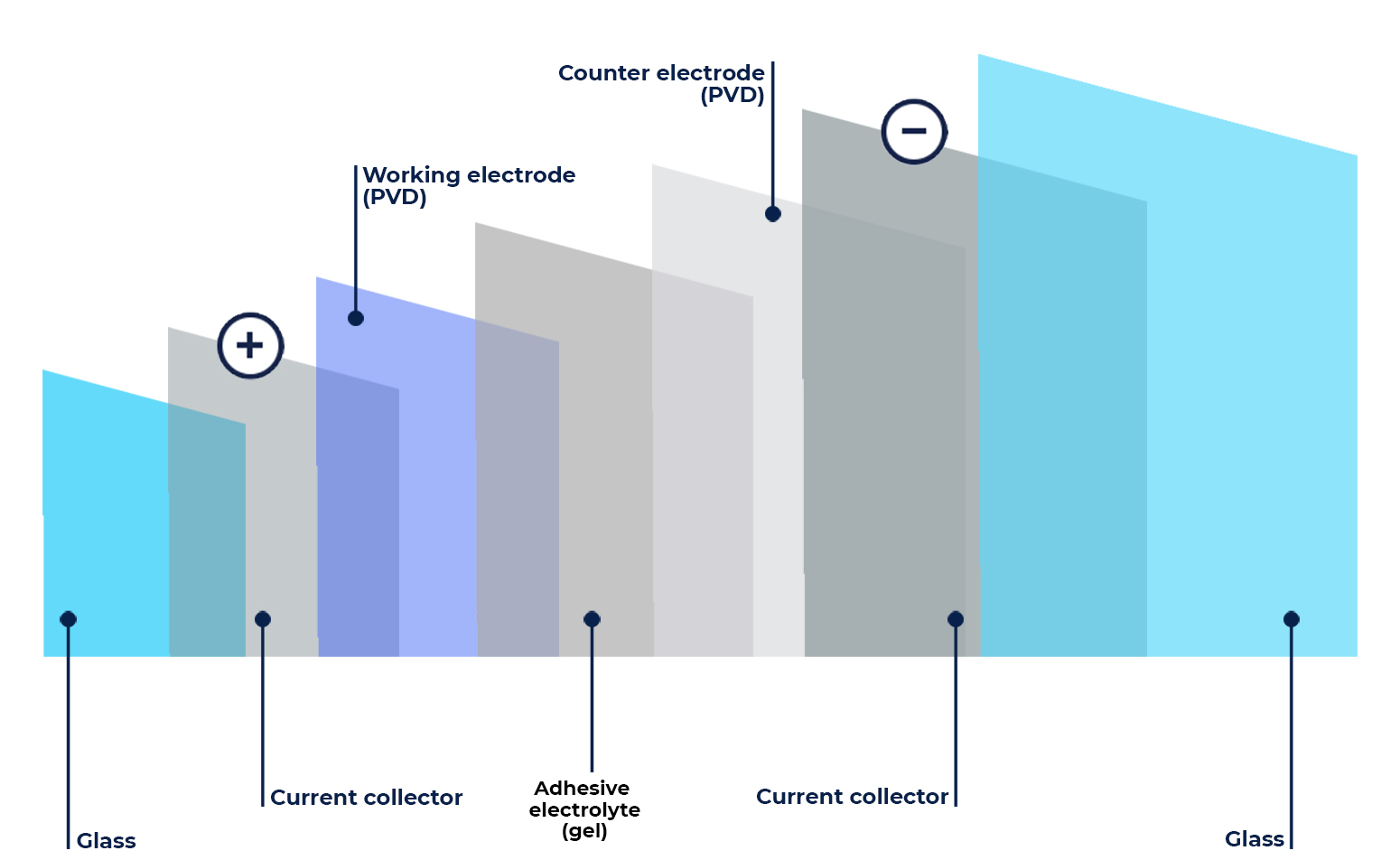

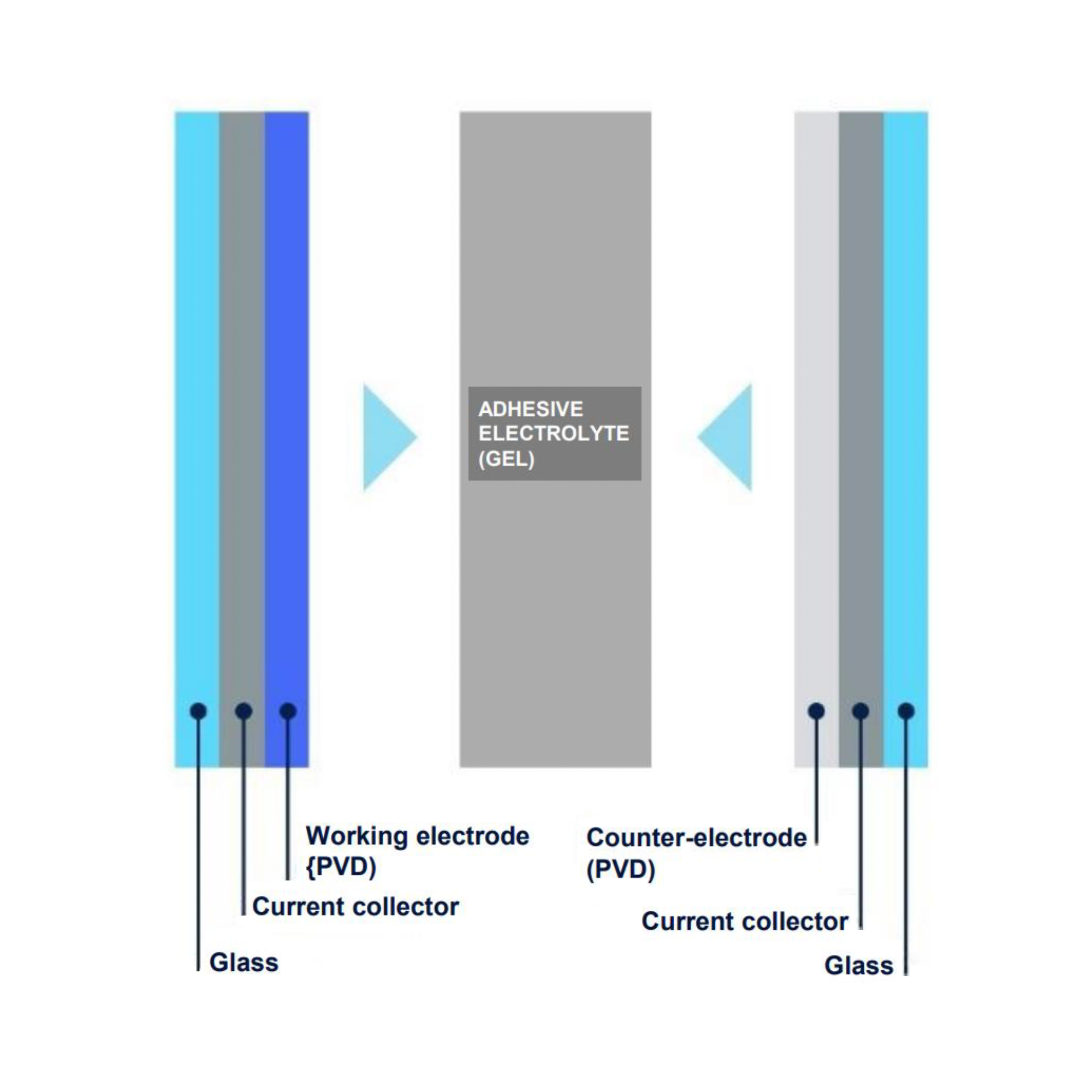

In most instances, electrochromic glass consists of a darkened electrode (an electrochromic electrode) and a transparent electrode (a counter-electrode with an ion-conducting electrolyte located between the electrodes (fig. 1). The nature of the materials used and the manner in which they are applied on the glazing surface may vary. This choice is left to the producer and is determined by a number of economic and technological factors influencing the consumer attributes as well as the cost of the product. In any of the versions, electrochromic glass is a galvanic device (a kind of a rechargeable battery) based on optically transparent materials.

An electrical potential when applied causes ions (normally lithium) to move towards the working electrode. This makes the working electrode colored until the apparent light transmission ratio required by the consumer is reached. When the power supply is off, the coloring of the electrode does not disappear remaining exactly the same as it was before. This means that electrochromic glass does not consume electricity permanently, but only when the light transmission mode is being switched. Inverse voltage application ensures that lithium ions move from the working electrode to the counter-electrode with the working electrode becoming discolored. The electrochromic unit becomes transparent, a process similar to a battery charging and discharging process.

Despite its apparent simplicity, electrochromic glass is in fact a sophisticated product as it is comprised of a large number of additional materials and various transition layers which reduce internal resistance or affect other important electrochemical properties of the entire galvanic system. Besides, it is as labor-intensive to assemble an electrochromic device as, for example, to produce lithium ion batteries.

Comberry has developed the TUNOX technology and a prototype electrochromic device (system) based on a combination of inorganic and organic materials.

System specifications:

The technology consists of replacing the solid-state electrochromic stack with a semi-solid-state stack. The inorganic electrolyte is replaced by a gel-polymer or a polymer electrolyte offering adhesive properties and good conductivity.

Gel-polymeric electrolyte properties:

Comberry, LLC (based in Ulyanovsk, Russia) is a tech company and a combinatory platform. It ensures multiple acceleration of R&D in PVD application of thin-film coatings. The company was established in 2013 with the participation of nano-centers of Ulyanovsk, the Republic of Mordovia and Dubna and in cooperation with Intermolecular, Inc. (California, USA).

The Comberry team is ready to adapt its technology to scale it up from production of small research batches to commercial production or to establish a joint electrochromic glass production company.